Katal

A Transportable Demonstration SkidProducing Cleaner Diesel Fuel with a Process Prototype

Diesel, the fuel most used in transportation, construction, farming and military vehicles and equipment, is major source of pollutants such as ground-level ozone and particulate matter. A Calgary company, Katal, has developed a unique hydrorefining process in order to produce a diesel fuel of superior quality that may lower emissions by as much as 38%. This improvement would considerably reduce the carbon footprint of the trucks and ships that use it.

While confident in their research and able to demonstrate the process in the lab, the company encountered difficulties scaling the process and employing it in the field. After some consideration, Katal decided to produce a mobile demonstration skid that would allow them to further experiment and refine the process at a larger scale, and showcase the technology to potential investors.

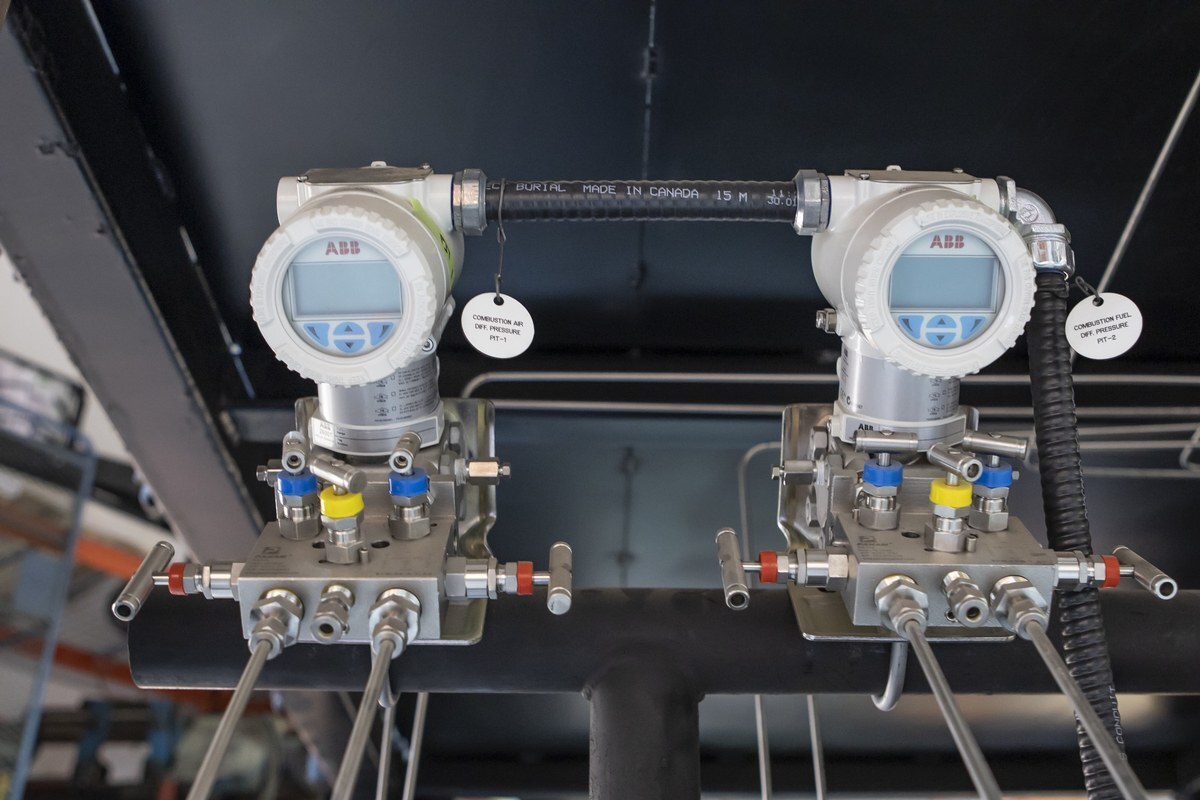

The Tangent team of mechanical, electrical and process engineers began to design a prototype that would implement the Katal hydrorefining process, allowing for precise control of critical variables. We met several challenges, as the technology requires fine controls and involves aspects of hazardous materials and areas compliance. As it was to be a demonstration facility, the prototype needed to be safe, transportable in a sea can, and thoughtfully constructed to look professional.

The team made extensive use of piping and instrumentation diagramming (P&ID) and process flow diagrams (PFDs) to develop a clear plan for the design. Through iterative and incremental design on the part of all involved engineering disciplines and careful project management, we were able to successfully commission and prototype the skid. With ample shop facilities and in-house millwrights, we were able to build the unit at Tangent, allowing for exceptional quality control and refinement throughout the build process.

Katal began with an innovative refining process to reduce the harmful emissions associated with burning diesel fuel, but encountered difficulties when trying to scale the process and deploy it in the field. Tangent’s passion for experimentation, process design expertise and exceptional project management made us the ideal team for this project.