Elavo

Proof of Concept Process SkidProcessing Drill Cuttings for Safe Disposal and Increased Profit

The disposal of drill cuttings, the solid material removed from a borehole and brought to the surface in the drilling mud as a part developing an oil or gas well, poses a dangerous and costly challenge. The removed material is suspended in a drilling fluid, and may be saturated with hydrocarbon – all which must be processed and separated before it can be returned to the earth in an ecologically responsible fashion. Elavo Energy Solutions, a funded start-up, has developed a new technology to separate oil from the soil, promising to reduce disposal costs and generate additional revenue by recovering the valuable hydrocarbon.

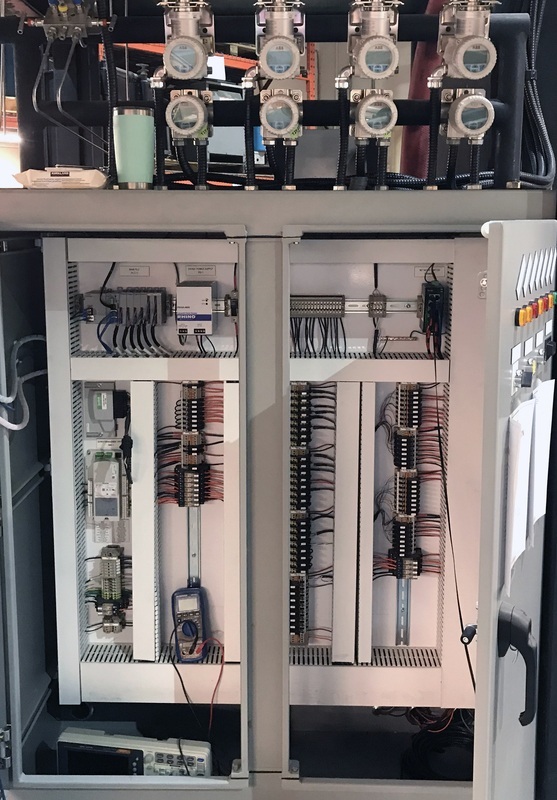

Elavo had considerable in-house expertise and experience in the oil and gas industry, but needed an engineering partner to help scale the technology to build a proof of concept processing skid. Tangent’s ability to work directly with researchers, integrate into existing engineering groups, and mobilize quickly to build physical prototypes made us the ideal partner for this project. Elavo contracted our team of mechanical, electrical and process engineers to produce a functioning demonstration prototype for their technology.

The result was a functional prototype that will provide Elavo with a facility for testing and refining their technology as they continue to build their business. Additionally, this proof of concept prototype will enable the company to demonstrate the technology to investors which will allow them to further scale the idea into a pilot plant.

Elavo began with an innovative process to decrease the cost and environmental impact of drill cuttings while developing a secondary source of revenue, but needed engineering support in order to build a large scale proof of concept processing skid. Tangent’s ability to mobilize quickly to produce physical prototypes, process design expertise and project management experience made us the ideal engineering partner for this project.